I brew a lot of small batches, typically in the 3 gallon range. Since I’m really the only beer drinker in the house, it doesn’t make a lot of sense for me to brew 5 gallon batches all the time. This allows me to brew a number of different styles, and have a variety on tap.

Now there are times when I’m trying out a new style, or making a significant change to a recipe, where I don’t want to waste 3 – 4 gallons of beer if something doesn’t work out. In those cases, I brew up a Pilot Batch to evaluate the beer before making the leap to a larger batch.

In this post we’ll be covering how I brew a pilot batch, and I’ll walk you through my brew day as I whip up a classic American Light Lager.

Pilot Batch Process

My pilot setup is a 2 gallon batch, that I keg in my 1.5 gallon Torpedo Keg.

This is the kicker. If I’m going through the effort to produce a beer that’s only going to net me about 12 pints, I really don’t have an interest in spending 4+ hours brewing this beer. So I take a Short & Shoddy approach to brewing my pilot batch.

My normal brewing process has me mashing for an hour and boiling for at least an additional hour. Using this abbreviated approach for my pilot beer saves me a considerable amount of time. I can typically get through my pilot batch, from start to fully cleaned up, in about 2.5 hours.

American Light Lager Pilot Brew Day

I’ve got an upcoming golf/fishing trip planned with the guy’s in the Fall, assuming this little pandemic doesn’t get in the way. This calls for something that is extremely crushable, light, and refreshing. Given Coors Light is the normal drink of choice for one of the guy’s, I thought an American Light Lager would do well for this trip.

Unfortunately, I haven’t brewed an American Light Lager, so before investing in a full 5 gallon batch that I’ll be sharing with close friends, I figured I should test it out first. Sounds like a perfect opportunity to brew up a pilot batch to see how things come out.

Bob Lite

Bob Lite, pun intended, is meant to mimic a classic American Lager. I’ll be using 2-Row Brewer’s malt, Flaked Rice, and a bit of Flaked Maize. I had quite a bit of Tettnang hops on hand, so we’ll go with that and do a first wort hop charge.

You can check out the results of this beer in a future post. Might be of interest if you’d like to see how fermenting warm with an American Lager yeast turns out.

This was the first pilot batch on my new eBIAB setup. So I wasn’t really sure what to expect with my brewhouse efficiency. My normal efficiency is pretty consistent at 67%, and given that I was using close to 30% adjuncts in this beer, I knew my efficiency would take a hit.

I guesstimated my brewhouse efficiency for this pilot batch would be 52%.

Pilot Batch Brew Day

I started the brew day the evening before by weighing out and milling my grains and prepping my water. Pretty much my typical process, as it does save some setup time on brew day.

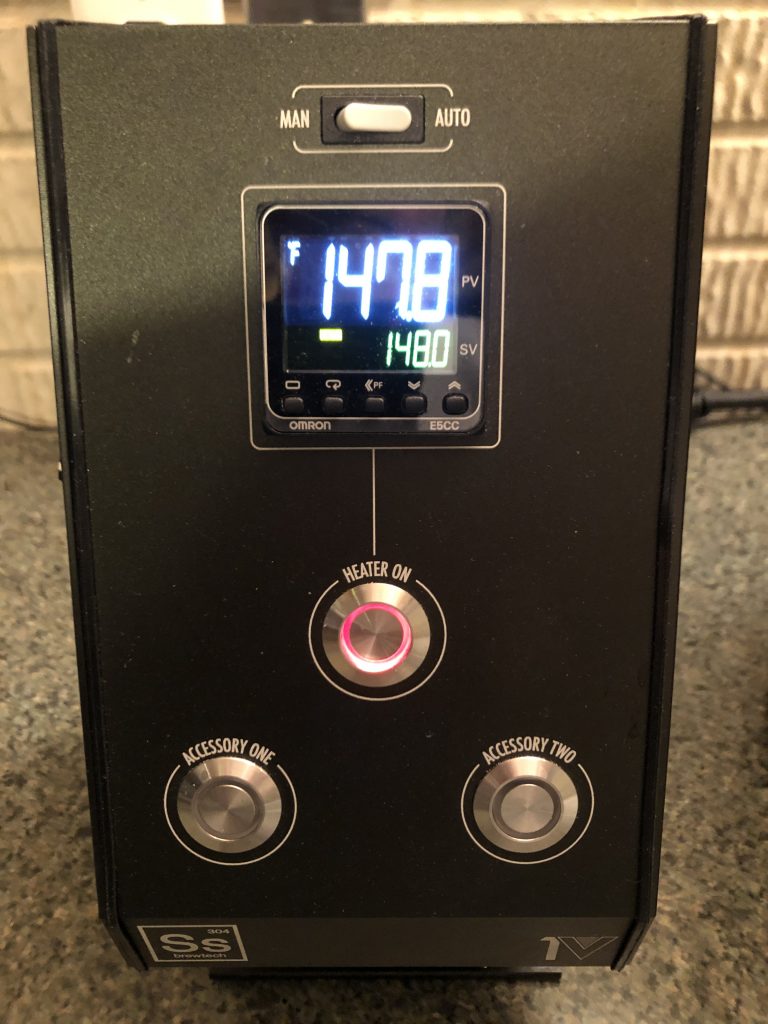

At 10:30 a.m the following morning, I flipped on the element to start heating my water, By 10:45 I was ready to mash in.

After a quick 30 minute mash, which I happened to stir at the 5 and 25 minute mark, I was ready to begin my boil. I added my first wort hop addition and set the heating element to 100% power.

A nice rolling boil commenced at 11:30, just one hour after my brew day started.

With the boil complete at noon, I began chilling with my CUS.S Brewing immersion chiller, about 5 minutes after the hour. I was able to cool my wort to the low 70’s after about 15 minutes.

I propped up the front of my kettle to let the trub settle for another 10 minutes or so before racking to my Anvil Fermenter. By 12:40, I had racked my wort and was already in the clean up phase.

By 1:00 p.m., 2 1/2 hours after I started, my brew day was complete. Well almost complete, I still needed to pitch my yeast.

I left my Anvil fermenter on the basement floor in an attempt to cool as much as possible. I wasn’t going with any temperature control, simply because my fermentation chamber was being used as a freezer. Damn you Covid!

After another 6 hours, I pitched my American Lager yeast into wort that was far too warm for a lager. Wort temp, a not so cool 68 degrees Fahrenheit.

Pilot Batch Results

As I stated previously, I went with a 52% brewhouse efficiency number for this pilot batch. After calculating my actual efficiency, I was at 57%. That’s really a lot better then I expected for a 30 min. mash.

This batch fermented for an entire week, without using temperature control, which hovered between 68 and 70 degrees Fahrenheit. Yikes!

I had more then enough on hand to fill my 1.5 gallon torpedo keg. After kegging, I lagered for an entire week before tasting.

Observations

Doing a small pilot batch is a great approach to use when trying out a new style or recipe. It’s even better when you can crank this pilot batch out in half the time it takes brewing a normal batch.

I’ve used this approach with my old equipment, and it’s far easier using my electric setup. I’ll continue brewing up pilot batches, especially now that I want to try out a number of new styles.

Cheers…

Leave a Reply